Buyers, auditors and customers are starting to expect reliable product facts at a simple scan, not just an email chain. Digital product passports turn that expectation into a single, scannable source of truth. For fashion wholesalers, they offer a single place to store and share facts about a product’s materials, origin, care, repair and end of life. That data travels with the item through a QR code or similar tag, so retailers, recyclers and consumers can scan and see the same trusted record.

This guide answers the question many teams are asking right now: what is a digital product passport, what does the legislation say in the EU and UK, and how do you roll it out with the systems you already use?

What is a digital product passport?

A digital product passport is a structured set of product data that is linked to the physical item through a unique identifier. In practice, that usually means a QR code, NFC tag or similar data carrier on the label that points to a secure record. The record contains standardised fields such as fibre composition, dye or finish details where required, country of origin, care and repair guidance, and links to certificates. For repairers and recyclers, it can also include disassembly information and details useful for sorting.

Why it matters in wholesale:

- It creates one reliable source of truth for buyers, compliance teams and service partners.

- It reduces back and forth with retailers when they ask for proof by putting approved documents behind a scan.

- It makes future circular services possible, such as take back, resale and fibre to fibre recycling.

The legislation in plain terms

European Union

The EU’s Ecodesign for Sustainable Products Regulation entered into force in July 2024. It creates the legal base for digital product passports across many product groups. In April 2025, the EU published its first plan under the ESPR. It lists the product groups that will get detailed rules first, and clothing and textiles are on that list. The earliest requirements could start from 2027 for the priority items, with more added over time. Passports will likely be reachable by a QR code or an NFC tag, use a common data format, and include clear guidance on who can see which fields.

United Kingdom

The UK does not yet have a final digital product passport law for fashion. However, UK policy is moving in the same direction as the EU. Work on Extended Producer Responsibility for textiles is ongoing, and industry bodies are preparing members for passport-style data needs. Many UK brands sell into the EU or run EU warehouses, so EU rules still affect them. The sensible approach is to build your data model once to meet EU requirements, and use it for UK buyers and partners too.

What this means day to day: If you sell in the EU, you’ll need passports for any products that are covered as the new rules take effect. If you sell only in the UK, start collecting the same data now so you’re in step with buyers and ready for future rules.

Why implementation starts with raw material data

A digital product passport is only as good as your inputs. Most of the fields you will be asked to share come from raw materials, bills of materials and approved tech packs. If you can name the fibre, finish, colour code, vendor and lot, creating the passport is simple. If those details are split across email, PDFs and ad hoc spreadsheets, it is slow and risky.

Start with these foundations:

- A clean library of fabrics, trims and packaging, with suppliers, certifications where relevant, lead times and costs.

- A product structure that links every style and variant to a bill of materials, measurement tables and care instructions.

- A change log that captures approvals and version history, so you can show when a spec changed and who signed it off.

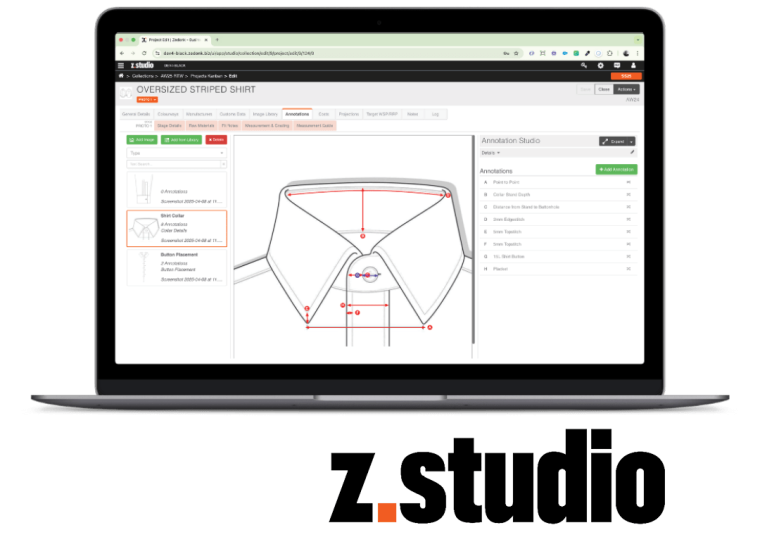

Zedonk covers this split of work clearly. Z.Studio PLM for fashion holds the design, sampling and tech pack detail. Z.Hub holds the ERP backbone for raw materials, purchase orders, stock, production and sales. The two share a common foundation, so Z.Studio is natively connected to Z.Hub. You can run Z.Studio on its own if you are starting small, or run both for an end-to-end setup without extra connectors.

What good digital product passport software looks like for wholesale

The fashion wholesale model has its own needs, so passport tools should reflect how seasonal ranges are built and sold. Start with a fashion-ready data model. Sizes, colourways and variants should be first-class fields, and one product record should generate all related SKUs without anyone retyping details.

Use standard identifiers such as GS1 QR codes. This ensures that a scan taken in a showroom, a warehouse or a returns centre resolves to the same trusted record.

Make data exchange straightforward. The software should offer simple APIs that push and pull information from your PLM, ERP, quality and compliance partners, so the passport mirrors the facts in your core systems.

Keep access under control. You should be able to make consumer-friendly fields public while limiting sensitive items to auditors, buyers or recyclers.

Link evidence in context. Certificates, lab tests and care guidance should sit alongside the product record and remain attached across seasons and batches.

Record change history. Every edit and approval should be time-stamped with an owner so it is clear who changed what and when.

Plan for scale. Bulk creation and update tools are essential because you will create passports for many SKUs each season.

How this maps to Zedonk

Z.Studio PLM centralises tech packs, measurements, grading, fit notes and annotations. It provides the structured specifications that feed a passport, including colourways and size runs.

Z.Hub ERP holds your raw material library, products and costings, production and inventory, allocation and fulfilment, sales order management and purchasing. These modules supply vendor names, lots, costs and stock references that make a passport useful in day-to-day operations.

The B2B Digital Showroom and the B2B Sales App present the same verified product data to buyers. Range plans and line sheets can reference the fields you plan to expose through a passport, which keeps what buyers see aligned with what a scan will show later.

What leading brands are doing today

Early movers are using digital product passports to solve real problems, not just to tick boxes. One common use is consumer care, where a QR code on the garment links to clear care and repair guides that help the item last longer.

Passports also support authenticity and resale. A quick scan can show proof of origin and trusted images that make listings credible.

On the recycling side, brands share fibre and finish details so sorters can process items more accurately and improve outcomes.

Retail partners want fast access to paperwork. With a passport, one scan takes them to certificates, conformity documents and country of origin proofs.

ERP features that make passport work easier

Passports thrive when ERP and PLM share clean data. The following features will save time and reduce risk:

- Raw materials and purchasing software. A structured library of fabrics and trims, with colour codes, costs and vendors, and purchase orders that reference those items

- Products and costings software. A single source of truth for style records, BOMs and prices that stays in sync with your tech packs

- Production and inventory software. Stock by location and lot, so returns, repairs and recycling partners can find what they need

- Sales order management and allocation software. Links between orders, deliveries and products, which helps retailers trace what they bought and when

- Document storage. A place to keep test reports and certificates that can be surfaced to the passport as needed.

A step by step plan for digital product passport implementation

Here is a simple, low-risk path that wholesale teams can follow over one or two seasons.

Phase 1. Scope and data audit

- List the territories you sell to, then map which product categories are most likely to require passports first. Textiles and apparel are high on the list in the EU

- Audit your data sources. Identify where composition, finish, certificates, care and supplier details live today

- Decide on the identifier you will use on the product. For most teams, this will be a QR code that points to a unique URL

Phase 2. Clean the essentials in PLM and ERP

- In Z.Studio, standardise tech pack templates so composition, care and measurements are captured the same way each time

- In Z.Hub, tidy your raw material library and product records. Make sure colours, lots and suppliers are consistent

- Set up a simple approval process for any data that will feed the passport

Phase 3. Build a minimum viable passport

- Pick five current styles across different categories

- Create a small set of fields that you know are required or likely to be required. Start with composition, country of origin, care, and a link to a certificate if you have one

- Print a sample QR and test with buyers, customer service and a recycling partner. Note what they find useful and what is missing

Phase 4. Connect and scale

- Use APIs or export jobs to pull approved data from Z.Studio and Z.Hub into your passport service

- Train your team to keep using the same fields and templates. The more consistent your data, the easier your next season becomes

- Expand the passport to more styles and deeper fields as delegated acts clarify the final list of required data

Practical tips for wholesale teams

- Treat the passport as a window onto data you already trust, not a new data silo

- Keep access simple. Make consumer-facing fields clear and helpful, and use permission fields for audit material

- Plan for season over season updates. Use versioning so a scan shows the right instructions for the batch at hand

- Agree ownership. Quality might own certificates, product development owns specs, and sustainability owns the narratives

- Work with buyers early. Share your approach so line sheets and showroom content match what a scan will reveal in store

How Zedonk helps you futureproof

Start where you are: run Z.Studio on its own to capture clean specs and grading, or link it with Z.Hub for end-to-end master data, orders and stock. Use only the modules you need – Raw Materials and Purchasing, Products and Costings, Production and Inventory, Sales Order Management, Allocation and Fulfilment, plus the B2B Digital Showroom and B2B Sales App – so your data stays clean and reusable. Avoid heavy integrations because Z.Studio is natively connected with Z.Hub, letting product and material data flow without middleware when both are in use. Stay flexible as EU delegated acts add new data points by extending templates and fields rather than rebuilding your stack.

A digital passport that opens doors

Digital product passports are on track to become mandatory for textiles in the EU in phases from later this decade, with the UK moving in a similar direction. The best way to prepare is to get your product data in order: use PLM and ERP together, run a small pilot with standard identifiers like GS1 QR codes, then scale as the rules are finalised.

If you want a simple, low-risk path, contact Zedonk. Z.Studio keeps specs, grading and approvals clean, and Z.Hub manages materials, costs, stock and orders so your passport data is consistent from day one.

A New Sampling & Tech Pack Solution from Zedonk.

A New Sampling & Tech Pack Solution from Zedonk.