In fashion, great ideas are just the beginning. Whether it’s the texture of a fabric, the cut of a sleeve, or a silhouette inspired by a gallery wall in Paris, turning that inspiration into a best-selling garment is anything but simple. Behind every finished piece is a complex web of decisions, collaborations, approvals, and logistics.

That’s where Product Lifecycle Management (PLM) comes in.

Far from just a tech buzzword, PLM is becoming an essential pillar in fashion businesses, from emerging designers to well-established labels. If you’re trying to scale sustainably, reduce errors, or just make sense of the chaos that is collection planning, understanding PLM could be your brand’s secret weapon.

Let’s dive into what product lifecycle management really is, how it applies specifically to fashion, and how your business can use it to its full advantage.

What Is Product Lifecycle Management?

Product Lifecycle Management (PLM) is the strategic process of overseeing a product’s development from idea to end-of-life. In the context of fashion, this means managing everything from initial sketches and raw material planning to sampling, production, and sales.

You can think of PLM as a single thread that weaves through every department, bringing together creative, technical, and commercial teams with one unified source of truth.

While ERP (Enterprise Resource Planning) systems are great for managing day-to-day operations like inventory, order processing, and financials, PLM sits a step earlier in the chain. It helps ensure the product is designed, sourced, and built correctly before anything hits the production line.

Without a PLM system, it’s not unusual for teams to rely on disjointed spreadsheets, long email chains, and a fair bit of memory gymnastics. But with a PLM approach in place, the lifecycle of every product becomes traceable, manageable, and, most importantly, repeatable.

Common PLM Terminology Explained

Let’s decode a few essential PLM terms that often come up in the fashion space:

- Bill of Materials (BOM): Think of this as the ingredients list for your garment. It includes every material component, down to the lining and zipper, along with quantities and supplier details.

- Tech Pack (Technical Package): A detailed guide that tells your manufacturer exactly how to construct the item. It includes design flats, dimensions, stitching details, and material specifications.

- Critical Path: A timeline that outlines key milestones in a product’s development, from design approval to sample sign-off and production deadlines.

- SKU Management: Tracking individual product variations like size, colour, or region-specific compliance requirements. Managing SKUs efficiently is vital for inventory and sales success.

- Sample Stage & Fit Approvals: Multiple rounds of sampling are typically required, and each must be documented and signed off to proceed confidently into bulk production.

By getting comfortable with this vocabulary, fashion professionals can communicate more effectively across teams and with suppliers, reducing missteps and saving valuable time.

Why PLM Is Essential in Today’s Fashion Industry

The fashion industry has undergone massive shifts in the past decade. Collections are dropping faster. Consumer expectations around sustainability and transparency are rising and global supply chains have never felt more fragile. In this context, product lifecycle management offers not just convenience, but resilience.

For example, consider the 2020-21 pandemic years. Brands that had digital, lifecycle-based systems in place were able to pivot quickly, adjusting their production timelines, reallocating inventory, and communicating with remote teams from wherever they were working. Others weren’t so lucky, but the benefits go well beyond crisis management:

Faster Time to Market

In the fashion world, timing is everything. A month’s delay can mean missing a key season or falling behind on trend relevance. PLM helps compress lead times by keeping the process visible and coordinated across all departments.

Fewer Errors and Better Quality

By working from one centralised system, teams avoid duplicating work or making decisions based on outdated versions of documents. This means fewer mistakes, more consistency, and stronger supplier relationships.

Improved Sustainability

While Zedonk doesn’t currently offer environmental impact tracking, having visibility into raw materials, purchasing, and production planning through our raw materials purchasing software solution makes it easier to make sustainable choices. Less waste, more control.

Enhanced Collaboration

Creative teams and supply chain managers don’t always speak the same language. PLM translates those conversations into shared, actionable information, whether your team is working in-house, remote, or overseas.

A Zedonk client in Copenhagen, for instance, credited lifecycle visibility with helping them keep three capsule collections moving concurrently. Their small team had previously juggled planning via spreadsheets. With a structured lifecycle approach, they cut sampling time by 30% and improved supplier lead time accuracy, without hiring additional staff.

Breaking Down the Product Management Lifecycle Process

Fashion is often romanticised, but the reality can be far more process-driven. While creativity drives the engine and sparks the beginning, execution is where a concept becomes a sellable product. PLM serves as the orchestrator that harmonises every stage of a product’s development, offering clarity and efficiency.

1. Concept Development

Designers begin to shape the creative direction of a new season, researching macro trends, examining customer feedback, exploring colour palettes, and sketching out potential silhouettes. Market insights, previous sales data, and seasonal direction all come into play here.

At this early juncture, Zedonk supports brands by facilitating early-stage raw material tracking. For instance, if you’ve previously used a particular cotton blend or recycled fabric, Zedonk allows you to assess current availability and supplier performance, helping you plan smarter for what’s to come.

2. Design Finalisation & Tech Pack Creation

Once concepts take form, designers translate sketches into tangible garment specifications. This includes technical flats, graded measurements, and fabric/trims detailing, all compiled in a tech pack.

While Zedonk doesn’t yet offer design software, its raw material functionality aids this phase by allowing teams to check what fabrics are available and cost-effective, ensuring design feasibility aligns with production capacity and budget.

3. Sample Rounds & Internal Approvals

Sampling often involves several back-and-forths. Fit samples, proto samples, and pre-production samples each serve a unique purpose, and meticulous documentation is crucial.

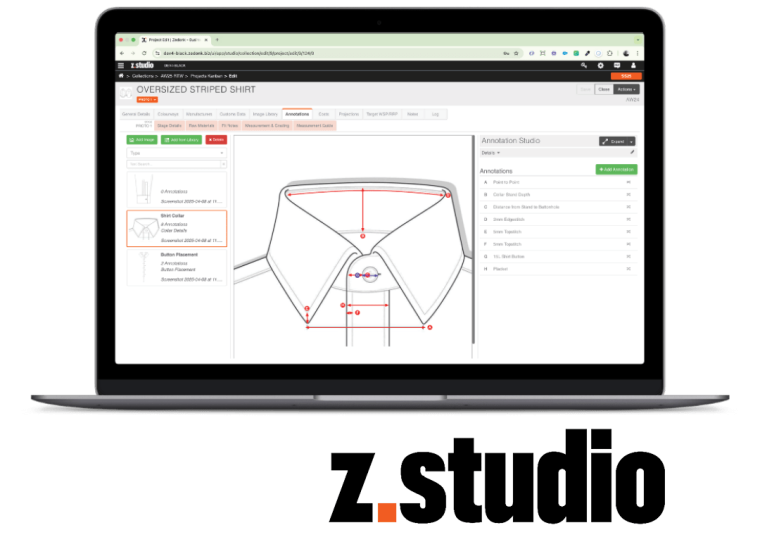

A PLM solution centralises this information. You can track which sample version is approved, maintain annotated feedback, and avoid costly confusion down the line. This becomes especially helpful when working with overseas factories where time zones and language barriers can complicate communication.

4. Sourcing & Cost Negotiations

This stage is a high-stakes balancing act: securing the right materials at the right price within the right timeframe. Brands negotiate MOQ (minimum order quantity), per-unit costs, and delivery windows.

Using Zedonk, brands can manage multiple supplier profiles, compare quotes, and track lead times all in one place. Having the BOM in sync with supplier data dramatically reduces missteps.

5. Production Tracking

Bulk manufacturing begins only after all designs, materials, and approvals are in place. From cut-and-sew to finishing and packaging, every production detail needs to be monitored.

Zedonk users can access their ERP system via iPad or tablet devices while on-site at factories. This is especially useful for updating delivery statuses, viewing shipment timelines, and reporting production progress in real time. The critical path becomes more than just a spreadsheet and acts as a live dashboard guiding daily decisions.

6. Sales & Launch

Once production is underway or complete, the focus shifts to sales activation. Collections are uploaded to wholesale platforms, showrooms are booked, and lookbooks are distributed.

Speaking of showrooms – in the digital age, an always-accessible, virtual showroom is an integral and versatile tool for both launches and sales. Once your collections are uploaded, potential customers can peruse the showroom at their leisure, place orders easily, and create a seamless flow of information from product presentation to order fulfilment.

In addition, Zedonk’s B2B sales app enables wholesale teams to manage buyer accounts, enter orders, and sync data with back-end stock availability. It may not offer third-party integrations, but its focused feature set makes it ideal for fashion businesses prioritising simplicity and reliability.

7. End-of-Life & Reflection

Even after a product exits the sales floor, the lifecycle isn’t truly complete. Brands analyse sell-through rates, customer returns, and supplier performance to refine future decisions.

PLM makes it easier to identify patterns: which fabrics consistently underperform, which suppliers met deadlines, and where bottlenecks occurred. These insights feed directly into the next season’s strategy, making the entire business more informed and agile.

Choosing a PLM System: What Fashion Brands Should Consider

Not all PLM systems are created equal, and not every fashion brand will need the same functionality. So how do you choose the right one? It’s a decision that impacts not only your workflow but your brand’s ability to grow, scale, and stay competitive in a rapidly evolving industry.

Integration Is Key

Your PLM system shouldn’t exist in a vacuum. The ideal system works in harmony with your existing ERP, inventory management, and raw materials purchasing workflows. For Zedonk users, this ERP integration is vital: connecting raw material planning with sample approvals, BOM data, and supplier information means fewer manual transfers and less risk of errors. Without integration, teams often find themselves duplicating entries across systems, wasting time and increasing the potential for mistakes.

Scale with Confidence

A scalable PLM platform is one that adapts as your brand evolves. Maybe today you’re running two seasonal drops a year, but in three years, you might be managing capsule collections across multiple regions. Look for a system that accommodates new team members, more complex collections, and international expansion. Features like timezone-specific workflows and region-based supplier management will become more valuable as you grow.

User Experience Matters

An elegant interface isn’t just a luxury, it’s a necessity. If your team finds the system confusing or outdated, they’re less likely to engage with it fully. Choose a system with an intuitive layout, searchable databases, and visual tools like calendars and kanban boards. For fashion professionals, especially creatives, the ability to easily upload images, link materials, and annotate designs makes a major difference in daily adoption.

Consider the Support

The best PLM providers aren’t just software vendors, they’re strategic partners. Look for a system that offers comprehensive onboarding, thorough documentation, and fast-response support teams. Ask whether customer service is included in your package or billed as an add-on. A responsive support experience during critical phases like collection development or production delays can make or break a season.

Cost-Effectiveness

PLM solutions come in all shapes and sizes. Some offer advanced features like AI-driven recommendations and custom automation, but that doesn’t mean they’re right for you. Instead, focus on what will actually streamline your process. Zedonk’s upcoming PLM release in 2025 is tailored to the realities of fashion SMEs, offering the essentials like BOM management, sample tracking, and supplier coordination, without forcing users to pay for functionality they’ll never use. This practical, value-driven approach is what sets a purpose-built system apart from bloated, one-size-fits-all platforms.

Ultimately, the “right” PLM system should feel like a natural extension of your workflow, not a hurdle. The better the fit, the more empowered your team will be to focus on what they do best: designing, developing, and delivering beautiful fashion collections.

Trends Shaping the Future of PLM in Fashion

Fashion never stands still, and neither does the technology behind it. Here are some key trends shaping the next wave of PLM solutions:

Cloud-Based Collaboration

More brands are moving their operations to cloud platforms. This means teams can access the latest product data anywhere in the world, anytime, especially useful during sourcing trips or overseas manufacturing visits.

Mobile-Friendly Workflows

PLM tools optimised for iPad and tablet devices will become the norm, helping teams log notes, update statuses, and review documents on the go.

Interoperability

Expect to see better integration across ERP, PLM, and wholesale systems. By breaking down data silos, brands can move faster and make smarter decisions.

Data-Driven Development

Brands are beginning to use past product data not just to track what happened, but to shape what’s coming. While Zedonk does not support forecasting, this kind of insight is becoming more common in lifecycle planning tools.

Final Thoughts

If fashion is an art, then PLM is the architecture that supports it. A thoughtful approach to product lifecycle management helps brands cut through the noise, streamline operations, and build collections with clarity and confidence.

Whether you’re a small label scaling up or a growing brand managing complex supply chains, PLM can unlock efficiency and creativity in equal measure.

And with Zedonk’s fashion PLM software, fashion businesses have a tool built specifically for their unique rhythm, one that honours the creative process while making operations smoother than ever. For more details and to discuss your needs with one of our team, please contact Zedonk today.

A New Sampling & Tech Pack Solution from Zedonk.

A New Sampling & Tech Pack Solution from Zedonk.